1、Gypsum method

Inject air into the slurry of the absorption tower to force the oxidation of CaSO3 to CaSO4 (gypsum), and the by-product of desulfurization is gypsum. Simultaneously blowing in air produces a more uniform slurry, making it easier to achieve a 90% desulfurization rate and control scaling and blockage.

The main advantages of limestone/gypsum method are: a wide range of applicable coal types, high desulfurization efficiency (some devices have desulfurization efficiency greater than 90% when Ca/S=1), high utilization rate of absorbent (can be greater than 90%), high equipment operation rate (can reach over 90%), high reliability of operation (currently the most mature flue gas desulfurization process), and abundant and inexpensive source of desulfurizer limestone. However, the disadvantages of the limestone/gypsum method are also quite obvious: high initial investment costs, high operating costs, large footprint, complex system management and operation, severe wear and corrosion phenomena, difficulty in treating the by-product gypsum (due to sales issues, it can only be stacked), and difficulty in treating wastewater.

2 、Magnesium oxide method

The magnesium oxide wet desulfurization process uses MgO as the desulfurization absorbent. MgO is prepared into Mg (OH) 2 supersaturated solution through an absorbent slurry preparation system. The supersaturated solution is pumped into the absorption tower and fully contacts with the flue gas, allowing the sulfur dinitride in the flue gas to react with Mg (OH) 2 in the slurry to produce MgSO3. The magnesium sulfite slurry discharged from the absorption tower is concentrated and dehydrated to a moisture content of less than 10%. It is then transported by conveyor to a magnesium sulfite storage tank for temporary storage, and transported away by sealed tank trucks according to the usage of by-products. This process is suitable for flue gas desulfurization of any coal with sulfur content, and the desulfurization efficiency can reach over 95%.

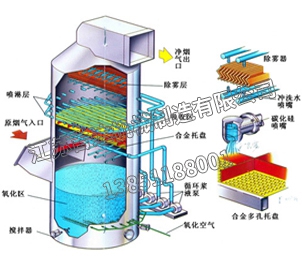

3、Seawater method

The seawater desulfurization process is a desulfurization method that utilizes the alkalinity of seawater to remove SO2 from flue gas. In the desulfurization absorption tower, a large amount of seawater is sprayed to wash the coal-fired flue gas entering the absorption tower. SO2 in the flue gas is absorbed and removed by seawater. The purified flue gas is dehazed by a defogger and heated by a flue gas heater before being discharged. After absorbing SO2, seawater is treated with aeration in an aeration tank to oxidize SO32- into stable SO42-, which is then discharged into the sea. Seawater desulfurization is generally suitable for flue gas desulfurization in power plants that are located near the seaside, have good diffusion conditions, use seawater as cooling water, and burn low sulfur coal.

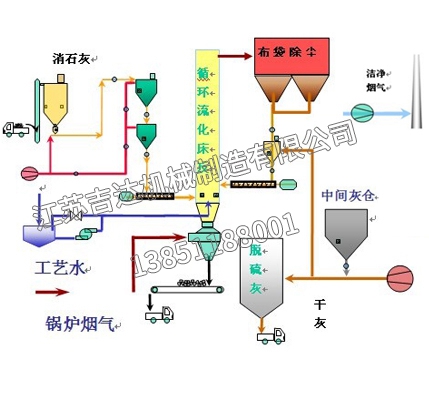

4、Double alkali method

The dual alkali flue gas desulfurization technology uses sodium hydroxide solution as the starting desulfurizer. The prepared sodium hydroxide solution is directly injected into the desulfurization tower to wash and remove SO2 from the flue gas, achieving the purpose of flue gas desulfurization. Then, the desulfurization products are reduced to sodium hydroxide in the desulfurizer regeneration pool and sent back to the desulfurization tower for recycling.

Advantages of dual alkali desulfurization technology:

The desulfurization efficiency is over 90%.

The desulfurizer uses sodium alkali and lime, and the clear liquid inside the tower is absorbed, effectively avoiding scaling inside the tower.

The liquid to gas ratio is small. Integrated desulfurization and dust removal.

One time investment saving, low operating costs, and high degree of domestic production.

Wide adaptability range.

5、Ammonia desulfurization

The ammonia method is an efficient and low-energy wet process. The ammonia method is a gas-liquid reaction with a fast reaction rate and high utilization rate of absorbent, which can maintain a desulfurization efficiency of 95-99%. The solubility of ammonia in water exceeds 20%.

The characteristic of the ammonia method is the resourceful utilization of SO2, which can recover the pollutant SO2 into high-value commercial products. The by-product ammonium sulfate is a high-performance nitrogen fertilizer with great market prospects in China.