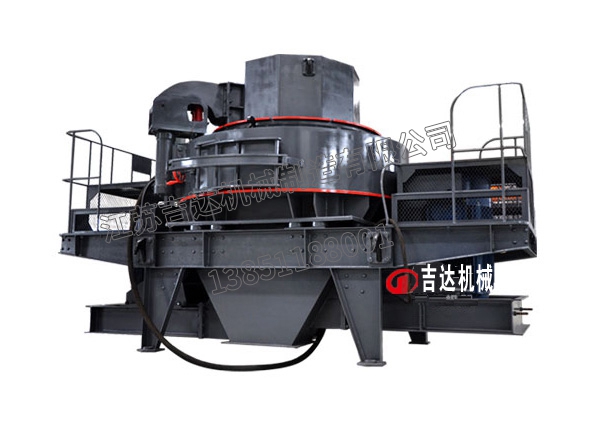

The JD series high-efficiency vertical axis impact crusher, commonly known as sand making machine or shaping machine, is the latest research and development result introduced by our company from authoritative German experts, and has been improved and designed in combination with China's mining conditions. It is currently the fourth generation high-performance sand making equipment with world advanced level in China.

【Feed particle size】: 30-50mm

【production capacity】: 60-520T/h

【application area 】:

Used in industries such as sand and gravel yards, mixing plants, dry powder mortar, quartz sand, and construction waste crushing, providing high-quality sand and gravel aggregates for highways, railways, construction, municipal engineering, hydropower dam construction, and concrete mixing plants.

【Applicable materials】:

River pebbles, quartz stones, limestone, pebbles, coal gangue, basalt, granite, diabase, etc

【Product advantages】

The processing capacity is large, the particle size is uniform, and the throughput can reach 520 tons/hour. Compared with traditional equipment under the same power, the output has increased by 30% and is stable. The product is cubic in shape, with good particle size, reasonable grading, and adjustable fineness modulus, especially suitable for manual sand making and stone shaping.

Low consumption of vulnerable parts, long service life, reasonable design of crushing chamber impact angle, minimal friction between materials and wear-resistant parts, directly reducing the cost of equipment use; Equipped with a German original thin oil lubrication station, it completely solves problems such as bearing heating, keeping the main shaft bearings at a constant temperature, extending maintenance cycles and service life.

Easy to operate and easy to maintain, with lightweight equipment, diverse installation methods, and convenient operation and use. Once the specific purpose is identified, only minor adjustments are needed to fully utilize its reliable performance; Equipped with a hydraulic cover opening device, it makes the maintenance and replacement of components inside the crushing chamber convenient and efficient, saving time and effort.

Advanced technology, energy saving and environmental protection, all core components are selected from internationally renowned brands (bearings use high-precision TIMKEN brand), ensuring low system failure rate; The equipment has low working noise and a unique air self circulation system, which greatly reduces the external exhaust volume, reduces dust, and is conducive to environmental protection.

【Working principle】

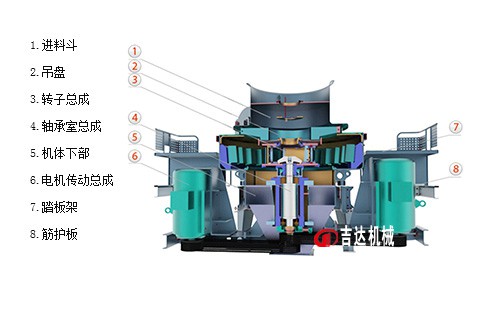

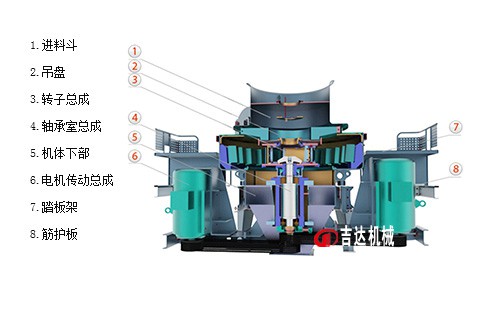

JD sand making machine uses advanced principles of selective crushing and cleavage crushing to directly apply sufficient kinetic energy to the material, and converts the kinetic energy into the crushing energy required to overcome the material through impact. The material fractures along its natural texture and cleavage planes, with good particle shape and low self consumption. This machine is capable of converting between two working principles: "stone to stone" and "stone to iron".

Central feeding: The material falls into the feeding hopper and enters the high-speed rotating impeller through the central feeding hole. It is rapidly accelerated inside the impeller, and its acceleration can reach dozens of times the acceleration of gravity. Then, it is ejected from the impeller at high speed. Firstly, it collides with another part of the material that falls freely after rebounding, and then impacts the material lining layer (stone striking stone) or counterattack block (stone striking iron) together. It is bounced diagonally upward and hits the top of the vortex chamber, changing its direction of motion, deflects downward, and collides with the material emitted from the impeller channel to form a continuous material curtain. In this way, a piece of material is subject to two to multiple probability impacts, friction, and grinding crushing effects in the vortex crushing chamber. The crushed material is discharged from the lower discharge outlet.

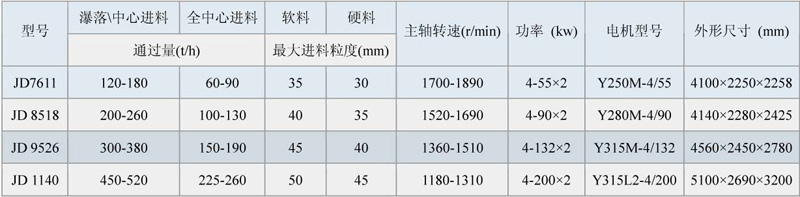

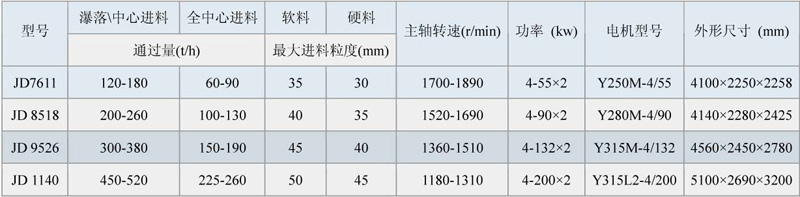

【Technical Parameter】