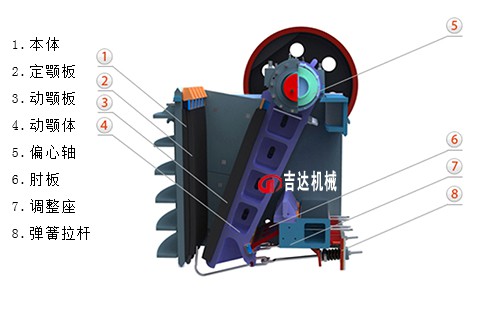

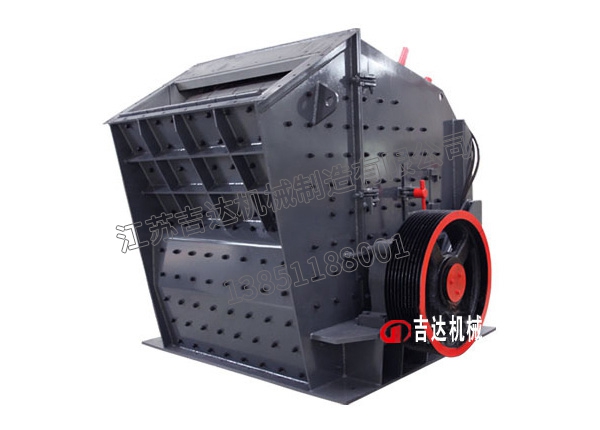

The PE series jaw crusher, commonly known as jaw crusher, is often used as a primary crusher in various stone production lines and ore crushing production lines. This product simulates the movement of two jaws in animals, squeezing, rubbing, and crushing materials in the crushing chamber through the movement of two jaw plates, the moving jaw and the fixed jaw.

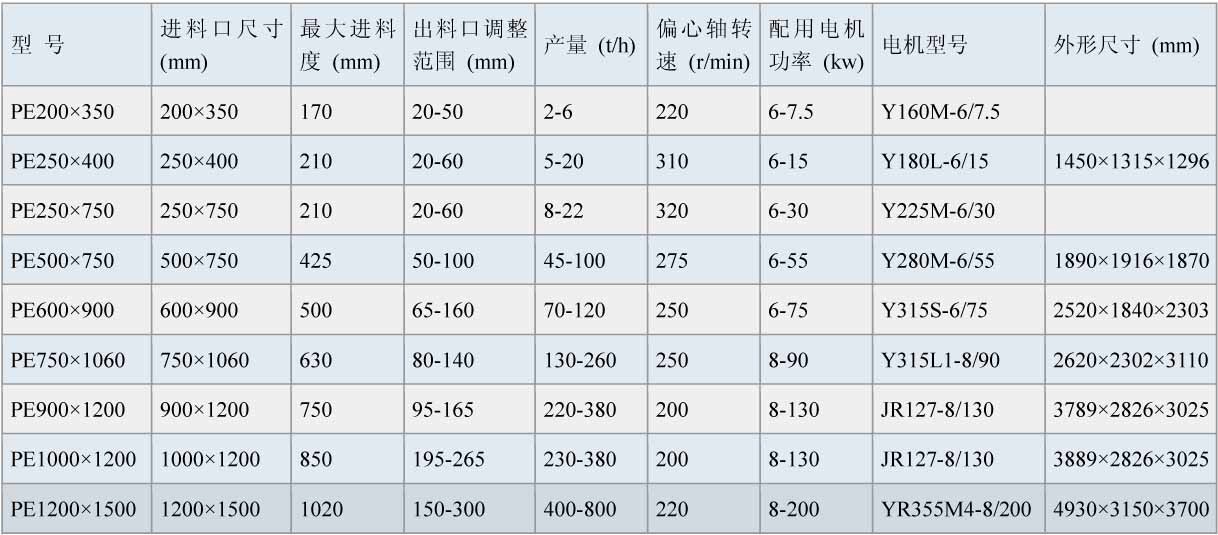

【Feed particle size】: 425-1020mm

【Production capacity】: 45-800T/h

【Application area 】:

Medium grained crushing of various ores and bulk materials in industries such as mining, metallurgy, construction, highways, railways, water conservancy, and chemical engineering

【Applicable materials】:

Granite, marble, basalt, limestone, quartz, river pebbles, iron ore, copper ore, etc

【Product advantages】

Good stability and high reliability

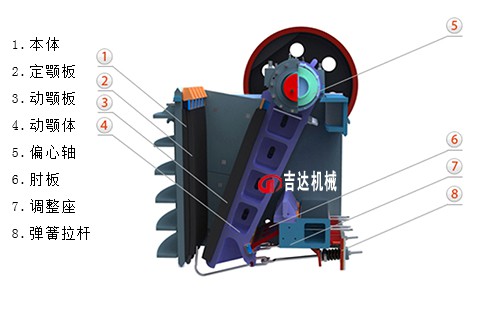

The movable jaw assembly is made of high-quality cast steel parts, and the heavy-duty eccentric shaft is also processed with forged blanks, all of which make the jaw crusher have extraordinary stability. Compared to other crushers of the same specifications, we use larger and more durable eccentric shaft bearings to provide higher load-bearing capacity and ensure its reliability.

Advanced technology with long service life

Adopting new manufacturing processes and utilizing advanced digital component processing equipment to ensure the precision of machine components; The use of high-end production materials greatly enhances its compressive and wear-resistant properties, greatly extending the service life of the machine.

Simple structure and easy maintenance

Through continuous improvement and optimization, the machine structure has been simplified while ensuring improved performance. The entire machine is easier to operate, maintenance is more convenient, and downtime for repairs is greatly reduced.

Large production capacity and good particle size

By adopting advanced crushing principles, the proportion of cubes in the product is significantly increased, and the needle shaped stones are reduced to a more uniform particle size.

【Working principle】

This product is powered by an electric motor, which drives an eccentric shaft through a triangular belt and a pulley. The moving jaw moves back and forth along a predetermined trajectory, crushing the material entering the crushing chamber composed of a fixed jaw plate, a movable jaw plate, and an edge guard plate. The finished material is discharged through the lower discharge port.

【Technical Parameter】