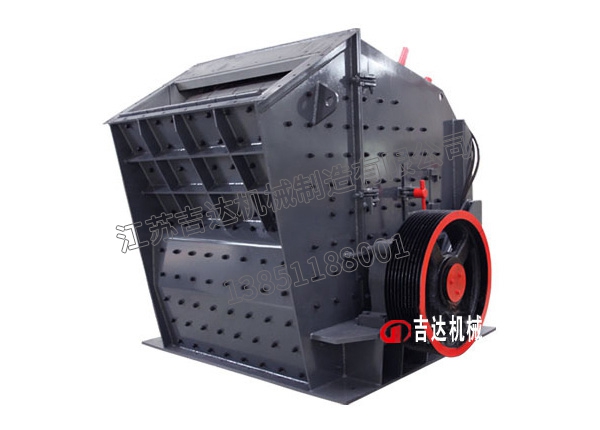

The PFD series impact crusher (European version of impact crusher) is mainly used in industrial sectors such as metallurgy, mining, cement, chemical industry, refractory materials and ceramics, as well as in fields such as highway construction, water conservancy engineering, construction gravel, and machine-made sand processing.

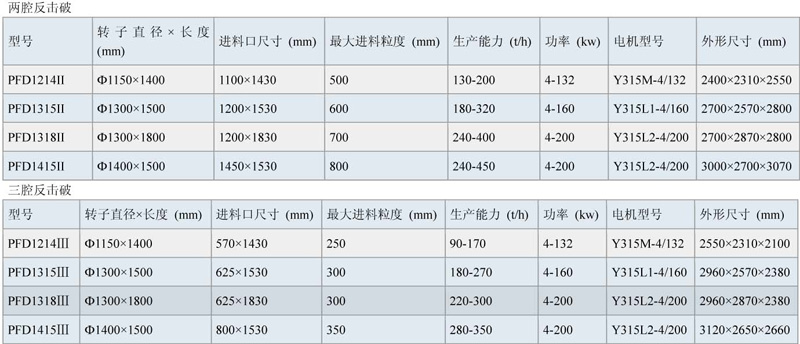

【Feed particle size】: 250-700mm

【Production capacity】: 70-400T/h

【Application area 】: Suitable for industrial sectors such as metallurgy, mining, cement, chemical, refractory materials, and ceramics, as well as fields such as highway construction, water conservancy engineering, construction gravel, and machine-made sand processing.

【Applicable materials】: Suitable for coarse, medium, and fine crushing of various soft and medium hard ores, such as limestone, feldspar, calcite, talc, barite, rare earths, clay, kaolin, dolomite, kaolin, gypsum, graphite, etc

【Product advantages】: The machine adopts a new manufacturing process and uses high-end materials for production; Heavy duty rotor design and strict testing methods ensure high-quality rotors; Meanwhile, the unique plate hammer fixing device enhances the reliability of the plate hammer.

Semi automated operation and maintenance are simple and fast

Optional hydraulic control system, which can quickly adjust the size and particle size of the discharge port through hydraulic devices; The automated hydraulic top opening device can quickly replace vulnerable parts such as hammers, reducing downtime and maintenance time.

Cast steel structure has high bearing capacity

The bearing seat of this series of impact crushers adopts an integral cast steel structure to ensure the stability of machine operation; Choose larger sized bearings to provide them with higher load-bearing capacity.

Two chamber crushing can simplify the process flow during coarse and medium crushing operations; Triple chamber crushing performs exceptionally well in fine and ultra fine crushing operations. Two types of chambers meet the crushing requirements of the vast majority of coarse, medium, and fine crushing operations.

【Working principle】:

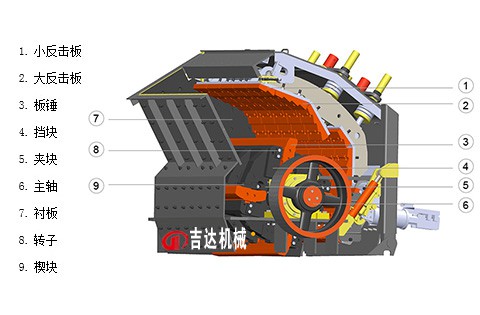

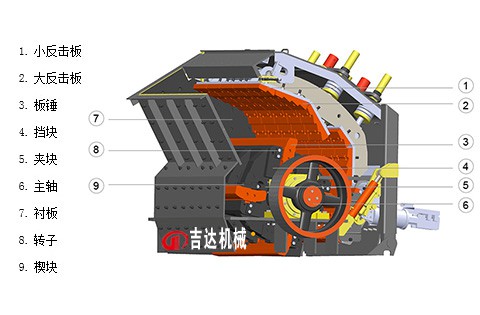

This machine is a crushing machinery that uses impact energy to crush materials. When the material enters the action zone of the plate hammer, it is crushed by the high-speed impact of the plate hammer and thrown towards the counterattack device installed above the rotor for further crushing, and then bounced back from the counterattack lining plate to the action zone of the plate hammer for re crushing. This process is repeated until the material is crushed to the desired particle size and discharged from the lower part of the machine. Adjusting the gap between the counterattack frame and the rotor frame can achieve the goal of changing the particle size and shape of the material. This machine adopts a spring safety device behind the counterattack plate. When non crushed materials enter the crushing chamber, the front and rear counterattack frames retreat, and the non crushed materials are discharged from the machine.

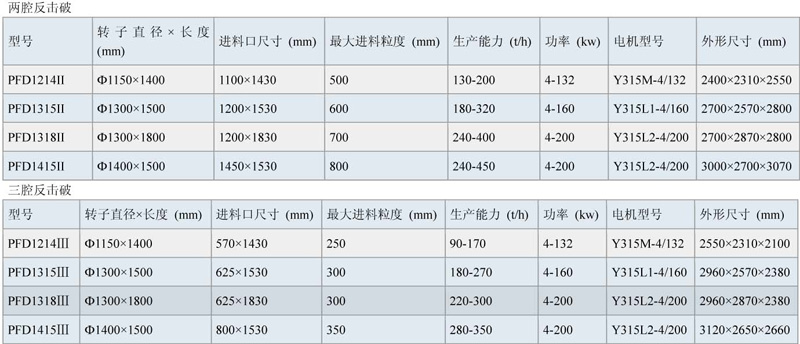

【Technical Parameter】: