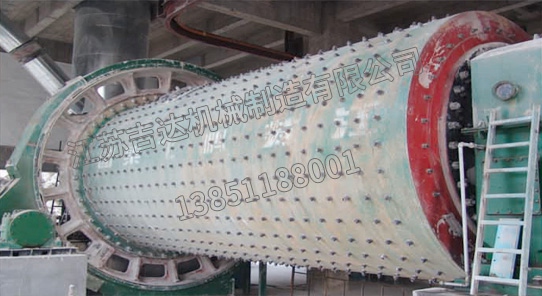

The JD spiral slurry screening device is an efficient screening device developed by Jeddah Company, which can effectively improve the hourly output of the closed-circuit screening mill, increase the specific surface area of cement, improve cement strength, and can be mixed with more admixtures. Its structure is to combine several crescent shaped fine pore sieve plates into a propeller shaped structure. The material filled on the spiral sieve plate rotates to a certain height and slides down from top to bottom on the inclined surface of the sieve plate under the dual action of gravity and stacking pressure for screening. Suitable for grinding are guided to the second bin for fine grinding, while coarse particles are returned to the first bin for fine crushing.

【Overview of JD Spiral Slurry Screening Device】

At present, most of the double layered sieve compartments in ball mills are arranged vertically, and the screening force for materials passing through the sieve gaps is the lateral stacking pressure of the materials. However, due to the small stacking height and weak stacking pressure, the screening speed of the material is slow and the screening efficiency is low.

The JD spiral slurry screening device is a new and efficient screening device developed by Jeddah Company, which can effectively improve the hourly output of the closed-circuit screening mill, increase the specific surface area of cement, improve cement strength, and can be mixed with more admixtures. Its structure is to combine several crescent shaped fine pore sieve plates into a propeller shaped structure. The material filled on the spiral sieve plate rotates to a certain height and slides down from top to bottom on the inclined surface of the sieve plate under the dual action of gravity and stacking pressure for screening. Suitable for grinding are guided to the second bin for fine grinding, while coarse particles are returned to the first bin for fine crushing.

Through the use of numerous manufacturers, it has been proven that when the width of the sieve slot is reduced to 1.5-2.0mm, its passing capacity can fully meet the requirements of closed-loop high-precision grinding. By using it, materials can be efficiently ground. As the gaps in the sieve plate are further reduced, it creates conditions for using the original micro forging, which can further improve the grinding efficiency of the mill and produce more qualified products.

【Double layer sieve partition compartment plate component】

| Serial Number | name | material | unit | quantity |

| 1 | Compartment grate plate | Cr3Mn13 | piece | 16 |

| 2 | Insulated compartment with perforated protective plate | Cr3Mn13 | piece | 16 |

| 3 | Discharge grate plate | Cr3Mn13 | cover | 1 |

| 4 | screen frame | 16Mn | piece | 8 |

| 5 | Partition sieve plate | stainless steel | cover | 1 |

| 6 | Standard parts | | cover | 1 |