【Main features of SM series grinding】

◎Simple grinding process: compact layout, high system operation rate. It integrates crushing, drying, grinding, and graded conveying, occupying an area of about 50% of the ball milling system, and can be arranged outdoors, reducing construction costs by about 70%.

◎ Less metal wear: Due to the fact that the grinding roller does not directly contact the grinding disc during operation, and the grinding roller and lining plate are made of high-quality wear-resistant materials, the service life is long and the wear is minimal.

◎ Strong drying ability: The hot air directly contacts the material inside the mill, which has strong drying ability and saves energy. By adjusting the temperature of the hot air, it can meet the requirements of materials with different humidity levels.

◎ High pressure and low-speed material bed grinding, low noise, system sealing operation, no pollution, good working environment.

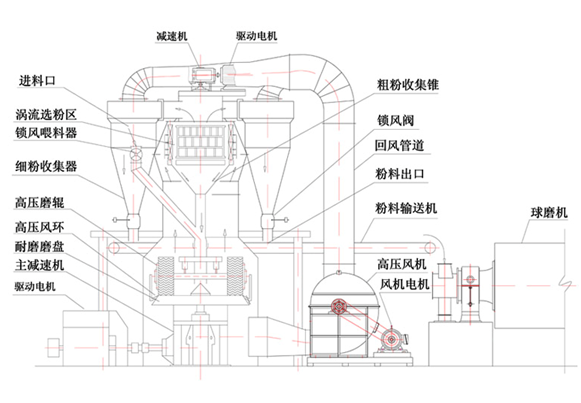

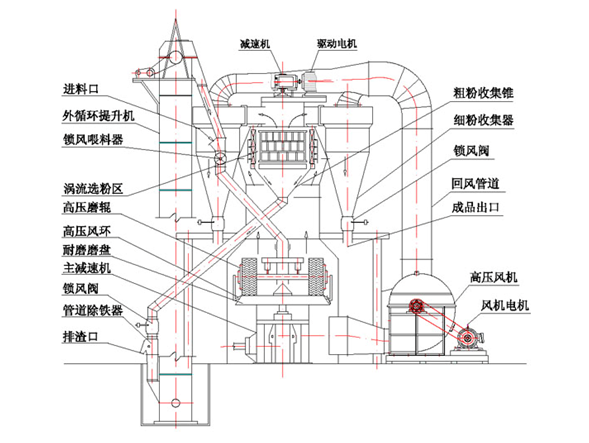

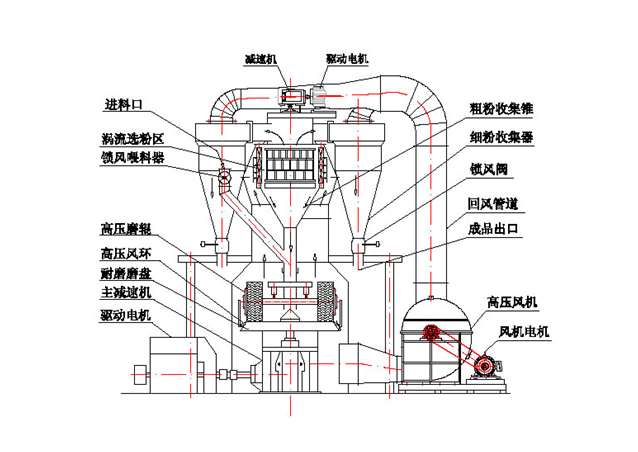

【SM Series Grinding Structure Description】

High pressure grinding roller, low-speed rolling, grinding roller pressure is 1.5 to 2 times that of conventional grinding rollers, resulting in higher grinding efficiency.

The grinding structure is more reasonable, with a fixed grinding disc and high-pressure rotation of the grinding rollers, making the grinding principle more in line with modern grinding theory.

Easy to operate and reliable to run, equipped with an automatic control system that can achieve remote control, easy to operate.

Equipped with a device to prevent direct contact between the roller sleeve and the grinding disc liner, it avoids destructive impact and severe vibration, achieving no-load start-up.

The grinding room is equipped with a uniform material distribution device, which can form a uniform and stable material bed on the grinding disc, and can timely discharge iron impurities inside the mill.

Stable product quality, short residence time of materials in the mill, easy to detect and control product particle size and chemical composition, reducing repeated grinding and stabilizing product quality. Integrate efficient eddy current powder selection machine, with sensitive fineness adjustment, reasonable product particle size distribution, high cement particle roundness coefficient, and improve cement strength by 10% at all ages.

Easy maintenance, by inspecting the oil cylinder, flipping the boom, and replacing the roller sleeve and lining plate, it is convenient and fast, reducing downtime.

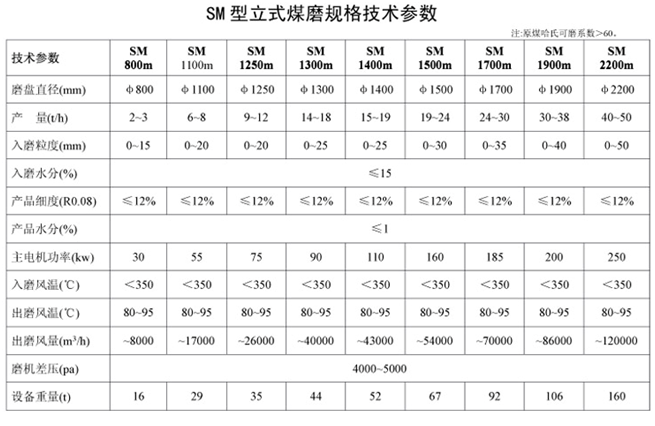

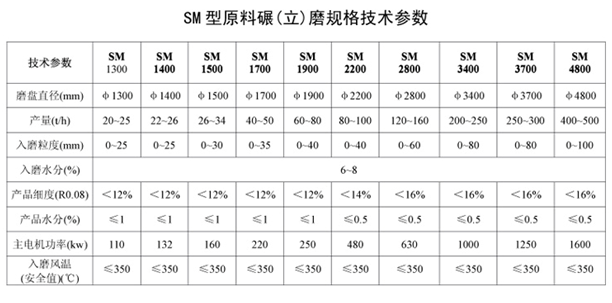

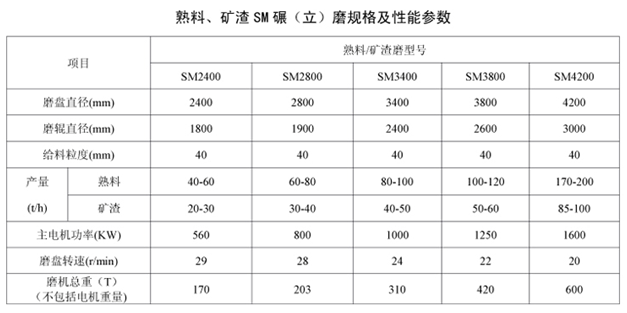

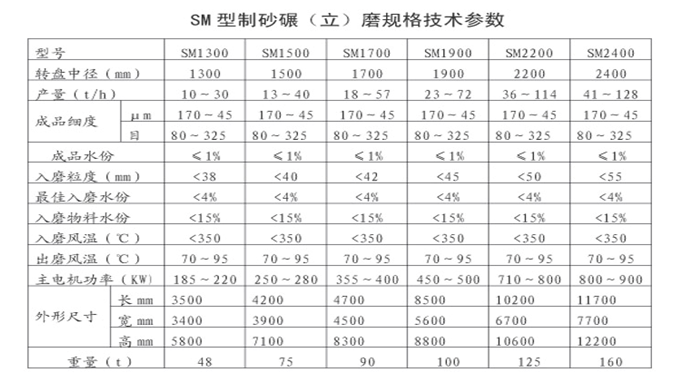

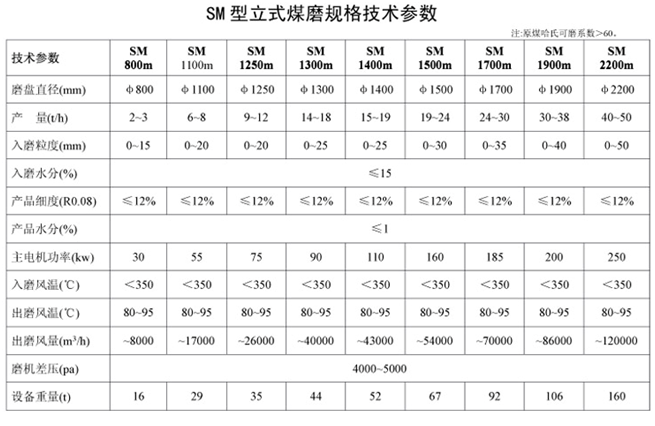

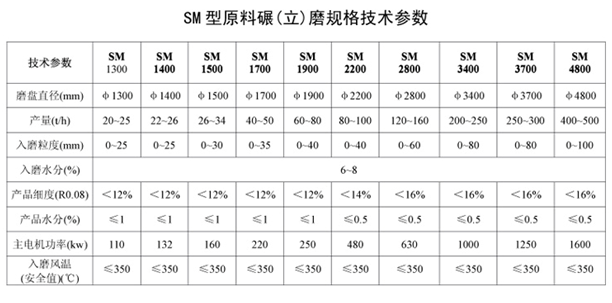

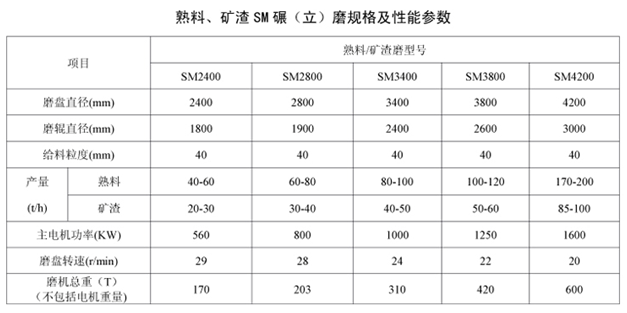

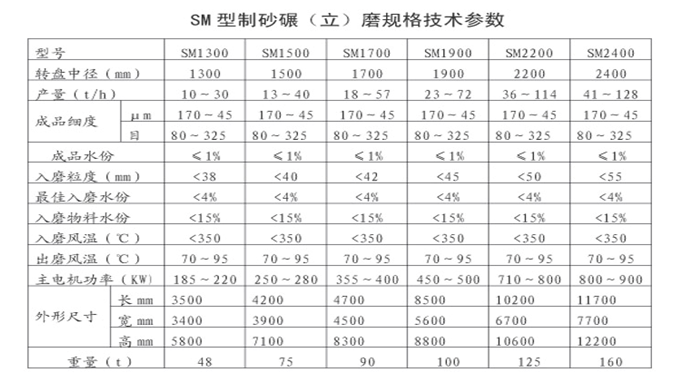

【SM series grinding related parameters】

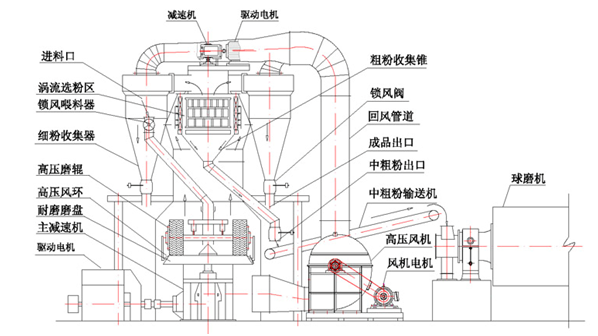

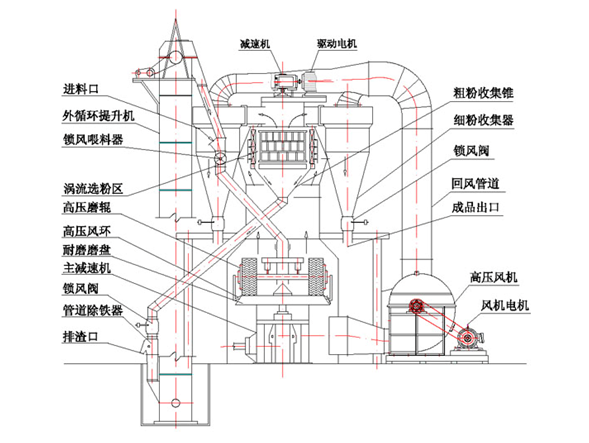

【Typical Process 1】Grinding of slag and clinker (excluding iron)

【Typical Process 1】Grinding of slag and clinker (excluding iron)

◆technological process:

After being crushed, the powder is blown up by high-speed airflow and sorted at the vortex classification point. The fine powder is carried by the airflow to four evenly distributed cyclone separators around and collected. The medium coarse powder slides along the pipeline to the outside of the mill and enters the lower pipeline iron remover after passing through the air lock valve. The iron impurities separated by the iron remover are discharged from the slag discharge outlet, and the remaining materials enter the circulating elevator and then fed into the mill for grinding.

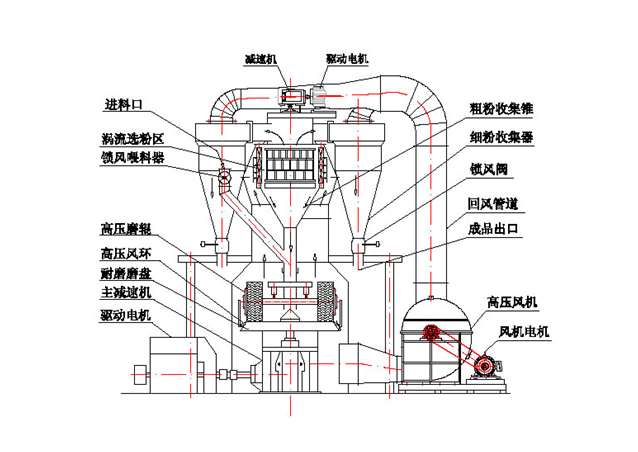

【Typical Process 2】Closed circuit final grinding process

◆ Process flow:

The material is fed into the vertical mill through the air lock feeder and falls into the center of the grinding disc. Under the action of the material distribution device, the material moves towards the edge of the grinding disc and is subjected to high-pressure grinding in the grinding area. The crushed material is blown up by the high-speed airflow generated by the high-pressure fan at the edge of the grinding disc, and large particles directly fall onto the grinding disc for re grinding. Most of the powder is carried by the airflow to the vortex powder separator for coarse and fine separation. The separated coarse powder falls back onto the grinding disc for grinding through the coarse powder cone and the discharge pipe. The qualified fine powder is collected in the cyclone separator uniformly distributed around the air flow, which is the finished product. The clean air flow enters the high-pressure fan for circulation.

◆ Process characteristics:

The entire grinding system has a simple process, compact structure, and integrates grinding, sorting, and collection into one. It occupies a small area and requires only half of the investment in civil engineering compared to conventional vertical mills. It comes with its own finished product collection equipment and does not require a large bag filter, reducing the total investment in system equipment by more than 30%.

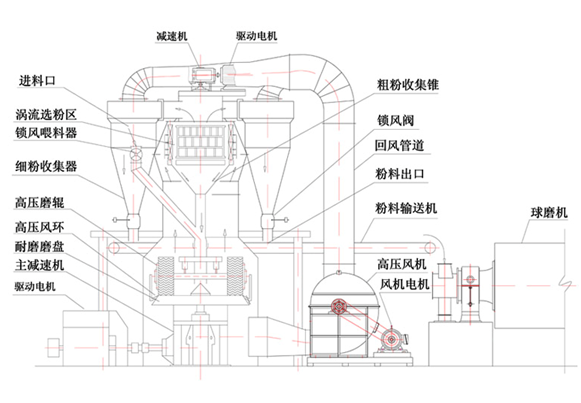

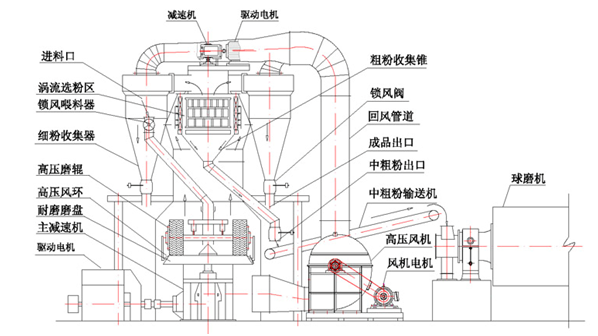

【Typical Process Three】Parallel grinding process

◆technological process:

The difference between parallel grinding process and closed-circuit final grinding process is that the medium coarse powder separated by the powder selector does not return to the grinding disc, but is sent out of the mill through a chute and a locking device, and then transported to the subsequent ball mill for grinding by a conveyor. The finished products after vertical grinding and ball grinding are mixed evenly by a mixing device to become finished products.

◆process characteristics:

After vertical grinding, an additional ball milling equipment is required, which will increase the initial equipment investment and land area by 50%. However, the spherical coefficient of the finished cement particles will increase, and the water demand for cement can be reduced.

【Typical Process Four】Series grinding process

◆technological process:

The material is fed into the vertical mill through the air lock feeder and enters the high-pressure grinding area. The crushed material is blown up by high-speed airflow at the edge of the grinding disc, and large particles directly fall onto the grinding disc for regrinding. Most of the powder is carried by the airflow to the vortex powder separator for coarse and fine separation, and the separated "coarse powder" falls back into the grinding disc for regrinding; Adjust the spindle speed of the powder selector to control most of the fine powder particles sorted within the range of 60-200 μ m, and then send them to the subsequent ball mill for grinding by the conveyor until the fineness is qualified.