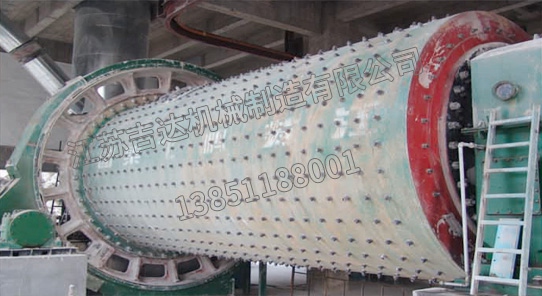

JDG series roller press machine

1、purpose

The JDG series roller press is the latest generation of grinding equipment for cement industry developed and researched at the end of the 20th century based on the introduction of German and British technology. It achieves a significant increase in cement raw materials and cement production with extremely low energy consumption and operating costs.

The JDG series roller press adopts a roller press based on material layer grinding technology and a matching VXS or VXR powder selector that integrates dispersion, grading, and drying in the grinding system. It can be combined with ball mills or form its own system to form various process flows, such as pre grinding, mixed grinding, semi final grinding, and final grinding systems. Due to changes in the grinding mechanism, the roller press and its system technology can reduce energy consumption by 50-100% and increase production by 100-300% in the grinding system; Suitable for grinding systems of cement raw materials or clinker, newly built or renovated factories, and changing the current situation of insufficient grinding capacity due to the adoption of new standards.

2、main features

◆ Roll surface technology (welding materials, equipment, and welding processes) comes from the world-renowned welding group, W.A Company in the UK, a professional manufacturer of hard surface welding. It effectively reduces the generation and propagation of microcracks during the welding process, hardens high hardness (>HRC58) and high toughness, and has a service life of over 8000 hours for roll surfaces with simple daily maintenance.

◆Using aviation hydraulic technology, German company REXROTH provides technical support and manufacturing as an OEM, making the JDG series roller press hydraulic system extremely reliable.

◆The hydraulic system of the JDG series roller press, when combined with a complete automatic control system, can achieve load control of the main drive motor of the roller press; Control and automatic correction of left and right gap deviation between two rollers; Fault self diagnosis technology.

◆The matching VX or VXR powder selection machine integrates the breaking, grading, and drying of the aggregate cake, and has the characteristics of low operating cost and high operating rate.

◆The supporting automatic control system adopts fuzzy control principle and integrates supporting components from world leading suppliers.

3、Specifications and main performance parameters:

| Model |

| 200-160 | 180-120 | 180-100 | 170-120 | 170-100 | 150-90 | 140-65 | 140-40 | 140-30 |

| Roller diameter | mm | 2000 | 1800 | 1800 | 1700 | 1700 | 1500 | 1400 | 1400 | 1400 |

| Roller width | mm | 1600 | 1200 | 1000 | 1200 | 1000 | 900 | 650 | 400 | 300 |

| through-put | limestone | t/h | 1030~1550 | 650~1000 | 518~800 |

| 496~757 | 400~588 | 265~405 | 163~249 | 122~187 |

| clinker | 1057~1507 | 678~966 |

| 577~824 | 458~623 | 364~495 | 245~334 | 150~204 | 113~154 |

| slag | 967~1316 | 620~844 | 413~585 | 476~647 | 379~539 | 315~428 | 212~288 | 130~178 | 98~133 |

| Feed particle size/maximum | %,mm | F95≤60

Fmax≤100 | F95≤55/Fmax≤;90 | F95≤50/Fmax≤85 | F95≤45

Fmax≤75 | F95≤42/Fmax≤70 |

| One pass average of cake size<2mm/0.09mm | limestone | % | 80/25 | 75/25 | 75/25 | 75/25 | 75/25 | 75/25 | 75/25 | 75/25 | 75/25 |

| clinker | 65/20 | 65/20 | 65/20 | 65/20 | 65/20 | 65/20 | 65/20 | 65/20 | 65/20 |

| slag | 70/18 | 70/18 | 70/18 | 70/18 | 70/18 | 70/18 | 70/18 | 70/18 | 70/18 |

| linear velocity /Max | m/s | 2.5 | 2.3 | 2.3 | 2.1 | 2.1 | 1.9 | 1.8 | 1.8 | 1.8 |

| Supporting motor power/Max | KW | 4500 | 3050 | 2860 | 2770 | 2400 | 1700 | 1150 | 710 | 500 |