一、overview

The JQM series air box pulse bag filter is a new type of high-efficiency bag filter equipment developed by our company based on the introduction of technology from Fule Company in the United States, absorption of the technical advantages of similar products in Germany, and combined with the actual situation in China. It combines the advantages of chamber back blowing and jet pulse bag filter to overcome the shortcomings of insufficient kinetic energy for chamber back blowing and simultaneous cleaning and filtering of jet pulse dust, expanding the application scope of bag filter equipment. This product combines the essence of similar products at home and abroad, combined with our company's environmental protection patent (patent number ZL 201710714676.0 for a multi-stage combined mesh electrode coal dust collector) technology, effectively improving the dust removal efficiency and operational reliability of the pneumatic pulse bag filter, extending the service life of the filter bag, reducing the labor intensity of operators, and becoming a reliable partner for enterprises to protect the environment.

The JQM series air box pulse bag filter is serving various industries such as casting, metallurgy, machinery, power, building materials, ore, cement, chemical industry, etc. with its reliable performance. It is dedicated to removing dust pollution and maintaining a good corporate image.

二、Product Features

1. Suitable for efficient concentration dust removal, such as O-Sepa powder concentrator, whose grinding system has a gas dust concentration of up to 1000g/Nm3, the JD type gas box pulse dust collector series can be directly processed without the need for primary dust removal equipment such as cyclone dust collectors.

2. The use of offline dust cleaning technology for chamber back blowing pulse dust cleaning not only avoids the phenomenon of secondary dust flying and re adsorption caused by online dust cleaning, but also does not affect the normal and continuous operation of the equipment, improving the dust cleaning effect and extending the service life of the filter bag.

3. The use of "filter bag self-locking sealing" technology has improved the sealing between the equipment and the filter bag, and enhanced the dust removal efficiency.

4. The equipment adopts an air box structure, which reduces local resistance and eliminates the inconvenience of installing filter bags.

5. The electromagnetic pulse valve adopts a double diaphragm structure, which has the advantages of sensitive control, high efficiency, and long service life.

6. The filter bag is made of our high-tech product - microporous film composite filter material. It can not only increase the filtration speed and reduce the operating resistance of the equipment, but also avoid the phenomenon of dust sticking to the filter bag due to condensation, which is difficult to remove. It is particularly suitable for dust removal of high temperature and high humidity dusty gases, such as cement, power and other industries.

三、Equipment structure

The JQM type pneumatic pulse bag filter is mainly composed of a bottom steel structure, ash hopper, upper box body, air inlet and outlet, filter bag, dust cleaning device, electrical control, and other parts. In addition, according to the actual situation, a silo wall vibrator can be installed on the outer wall of the ash hopper, and a star shaped ash discharge valve or screw conveyor can be installed at the ash hopper discharge port to discharge the ash.

四、Working principle

1. Filtering principle

The dusty gas enters through the air inlet and when passing through the ash hopper, some large particles of dust in the gas are separated by inertial force and directly fall into the bottom of the ash hopper. The dusty gas enters the filter bag filtration area of the middle box after passing through the ash hopper. The gas passes through the filter bag, and the dust is trapped on the outer surface of the filter bag. The purified gas enters the upper box through the filter bag and is then discharged through the air outlet.

2. Dust cleaning principle

As the filtration time prolongs, the dust layer on the filter bag continues to accumulate, and the resistance of the dust removal equipment continues to rise. When the equipment resistance rises to the set value, the dust cleaning device begins to clean the dust. Firstly, a compartment lift valve is closed to cut off the filtered gas, and then the electromagnetic pulse valve is opened. Compressed air rapidly expands inside the upper box in a very short time, stripping off the dust that has poured into the outer surface of the filter bag and falling into the ash hopper. After the dust cleaning is completed, the electromagnetic pulse valve closes, the lift valve opens, and the chamber returns to the filtering state. The cleaning process is carried out sequentially in each room, starting from the cleaning of the first room and ending with the next cleaning cycle.

3. Dust collection

The dust that is intercepted through filtration and dust cleaning work falls into the ash hopper and is then centrally discharged from the ash hopper.

五、Electrical control

1. Dust removal control method

The cleaning control method of JQM series pneumatic pulse bag filter generally adopts the timing method, or the fixed resistance method can be used.

The timed method is to clean the dust room by room according to the set time interval.

The fixed resistance method is based on the control of the pressure difference inside and outside the filter bag, and the signal sent by the differential pressure transmitter is passed through the electrical control device to clean the dust room by room according to the set program.

2. Functions of electrical control devices

The JQM type pneumatic pulse bag filter is centrally controlled by a microcontroller and can be divided into automatic and manual modes. During debugging and equipment maintenance, manual control is used, while automatic control is used under normal operating conditions of the equipment.

3、Operation method

① Power on operation

Check all electrical wiring, close all power switches after the differential pressure transmitter, wait for the fan to run, and when the feedback signal enters, the equipment will start running.

② Pulse dust cleaning

Pulse cleaning is carried out using automatic control. When the switch on the pulse controller is pointed to Demand, the fixed resistance method is used for dust cleaning. The red pointer on the meter is used to set the upper and lower pressure difference limits. When the resistance of the equipment exceeds the upper limit value, the pulse spraying starts to operate.

③ Ash unloading control

Ash unloading can be done manually or automatically. When using manual mode, press the "Ash Unloading Operation" button on the control cabinet to start unloading; Press the 'Ash Unloading Stop' button to stop the ash unloading process.

六、Model and specifications

JQM-N×S-A

The JQM series air box pulse bag filter series is divided into two forms: A and B. According to the actual needs of users, JQM pneumatic pulse bag filter can also be combined into non-standard equipment.

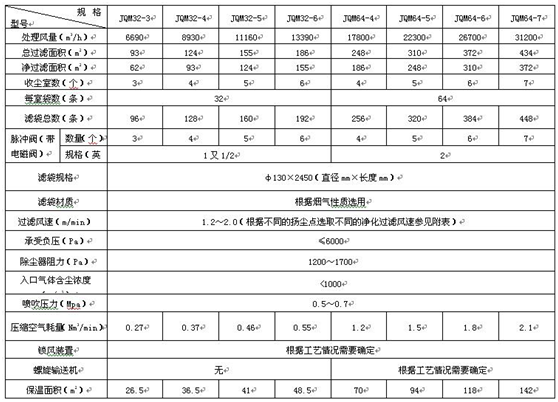

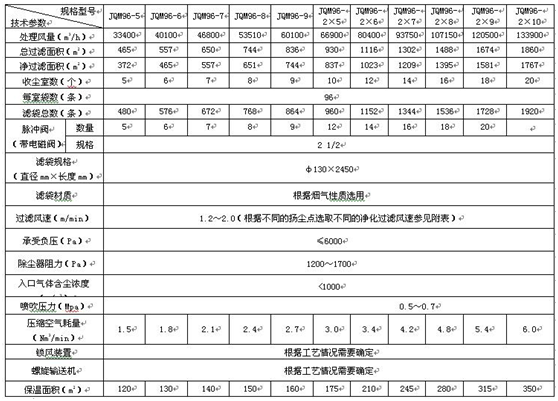

【Model and Technical Parameters Table】

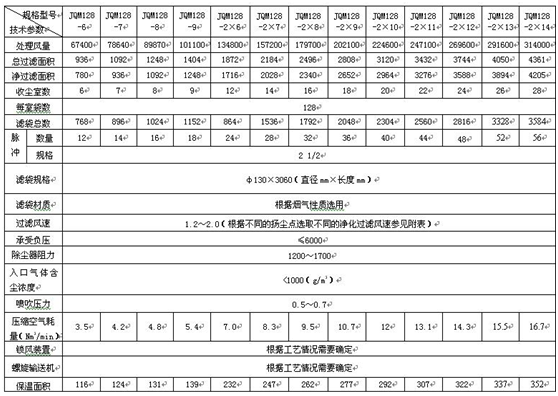

Table 1: Technical Performance Parameters of JQM32 and JQM64 Offline Pulse Bag Filter

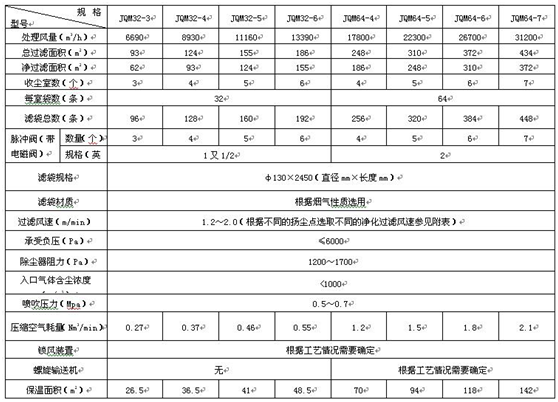

Table 2: Technical Performance Parameters of JQM96 Offline Pulse Bag Filter

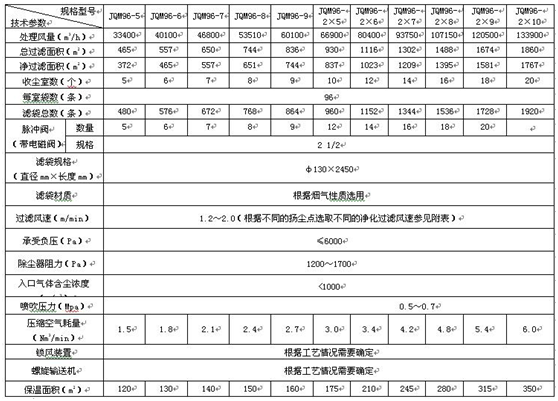

Table 3: Technical Performance Parameters of JQM128 Offline Pulse Bag Filter

Note: 1. The net filtration area in the table refers to the filtration area of a chamber during dust cleaning.

2. The gas consumption in the table refers to the gas supply situation of the factory. If a separate air compressor is set up, the gas consumption in the table should be multiplied by a factor of 1.3.

3. The processing air volume in the table is calculated when the gross filtration wind speed is 1.2m/min. It is only used for selecting the processing air volume directly according to the table when the dust concentration at the user's dust source point is less than 200g/m3 (standard) and the net filtration wind speed is also unknown.

七、Patent certificate: