一、 Overview

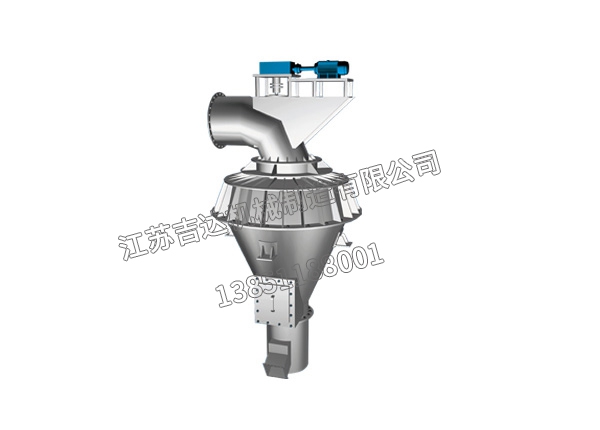

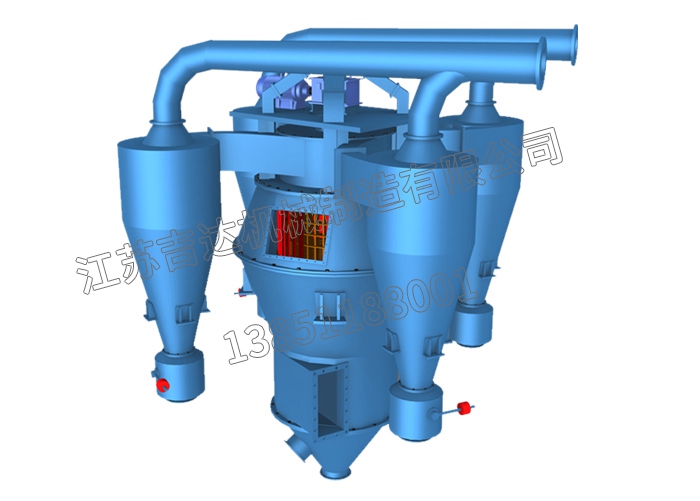

The JD series combined dynamic powder selection machine is a new generation of high-performance powder selection machine developed in China, which integrates coarse powder separation and horizontal vortex powder selection, based on the introduction, digestion, and absorption of France's wind swept coal mill specialized dynamic powder selection machine.

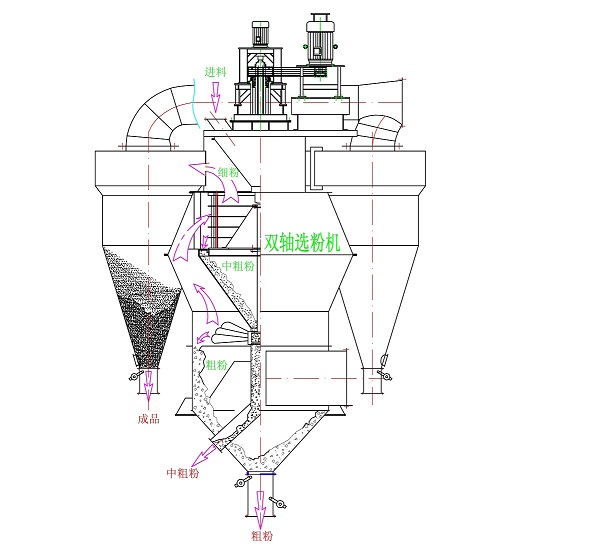

二、 Working principle

The air from the wind swept mill carries the material into the powder separator through the lower air duct, and after rectification by the inner cone, it slows down and rises along the annular channel between the outer cone and the inner cone. The coarse powder in it slides into the coarse powder collection cylinder through gravity settling along the outer cone wall to achieve gravity sorting. The air after gravity sorting carries the material particles and forms a stable horizontal vortex powder selection zone between the guide vanes and the rotor under the guidance of the guide vanes and the rotation of the rotor. The dust particles moving in the vortex will be simultaneously subjected to the effects of gravity, wind force, and rotational centrifugal force. Small and slight particles will be sucked into the rotor through the air flow and enter the rear dust collector as finished fine powder, which will be separated. Coarse and heavy particles fall and are collected in the coarse powder collection cylinder through the inner cone, returning to the mill for further grinding. Changing the rotor speed can effectively adjust the fineness of the finished product.

三、 Technical features

On the basis of drawing on advanced international powder selection technology, our company has further optimized the structural parameters of the JD series combined dynamic powder selection machine using aerodynamic analysis methods. The internal structure of the JD series combined dynamic powder selection machine produced by our company is more reasonable, the powder selection efficiency is higher, and the energy-saving effect is more obvious.

It mainly has the following characteristics:

1. Large output and wide operating conditions

The wind sweeping and grinding system equipped with JD series combined dynamic powder selection machine can increase the output by 20% -50% compared to the wind sweeping and grinding system equipped with static powder selection machine. The advanced and reasonable structure allows for a wide range of variations in powder selection air volume and output without affecting powder selection efficiency, and its grading performance is very stable.

2. Efficient and energy-saving, with low equipment resistance

The JD series combined dynamic powder selection machine adopts aerodynamic analysis method to optimize the entire flow field, which significantly reduces equipment resistance, improves powder selection efficiency, greatly reduces power consumption of the driving motor, and has a very obvious energy-saving and consumption reducing effect. The airflow inside the powder selection machine rotor only rises and does not rotate relative to the rotor. By utilizing the reduced momentum moment of the airflow entering the rotor, it can save driving power and reduce wear. Numerous user feedbacks indicate that using our company's JD series combination dynamic powder selection machine can save energy by more than 30-40%, and users have benefited greatly.

3. Easy to operate, convenient to adjust fineness

The main motor of the JD series combined dynamic powder selection machine can be remotely controlled, making operation very convenient. By changing the speed of the main motor of the powder selector, the fineness of the product can be adjusted within a large range.

4. Low wear and tear, low maintenance cost

The easily worn parts of the JD series combined dynamic powder selection machine, such as the inner cone, hub sleeve, guide vanes, and rotor blades, are made of wear-resistant materials or treated with wear-resistant processes, resulting in a low wear rate and extremely low maintenance costs.

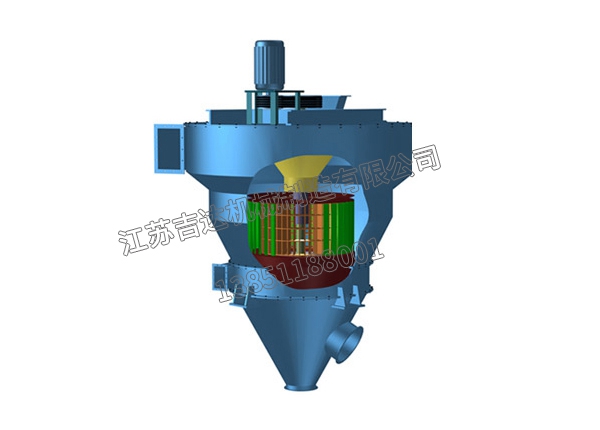

四、 Main structure

The JD series combined dynamic powder selection machine is mainly composed of a driving part, a rotating part, a housing part, and a lubrication system.

1. Drive section

The driving part consists of a driving motor and a reduction device. The driving part is generally a vertical motor with a belt pulley reduction transmission device. According to user requirements, a horizontal motor with a direct axis reduction gearbox can also be used. The motor adopts the Y series motor, and the current frequency of the motor is changed by an AC frequency converter to cause a large range of changes in the motor speed, or an electromagnetic speed regulating motor is used for speed regulation.

2. Rotating part

The rotating part is the core of the powder selection machine for grading and refining powder selection. It consists of a main shaft and a rotor, and is driven by a motor after deceleration. The main shaft is installed inside the hub sleeve, with the upper part of the hub sleeve vertically suspended on a bracket and the lower part tightened and fixed by a screw rod. The upper part of the main shaft is equipped with a large pulley or connected to the reduction gearbox through a coupling, and the lower part is connected to the rotor. To ensure sufficient lubrication of the bearings inside the shaft sleeve and prevent dust particles from entering, lip seals are installed at both ends of the shaft sleeve to prevent dust and oil leakage. The outer surface of the hub sleeve is coated with wear-resistant ceramic plates to prevent wear from airflow. The rotor has three layers of partitions: upper, middle, and lower. The upper plate is equipped with a sealing ring, and the rotor blades are installed between the upper and lower plates, evenly distributed along the circumference for easy replacement. To ensure the smoothness of the work, the rotor body was precisely balanced by the "Shen Ke" electronic dynamic balancing machine.

3. Shell part

The shell is the main load-bearing component and flow channel of the powder selection machine, mainly consisting of sheet metal welded parts. For the convenience of observation and maintenance, there are multiple manholes on the shell. There are evenly spaced guide vanes installed inside the shell, which guide the airflow to form a stable horizontal vortex field. A baffle plate and a sealing groove are installed on the inner ring of the air guide vane. To reduce the wear of the airflow, wear-resistant ceramic plates are pasted on the inner wall of the bent pipe, and the guide vanes and inner cones are treated with wear-resistant technology.

4. Lubrication system

The main bearings of the JD series combined dynamic powder selection machine are lubricated with molybdenum disulfide lithium based grease using a dual channel dry oil pump, and can also be lubricated with thin oil according to user requirements. When lubricating with thin oil, it is recommended to use N-68 anti-wear hydraulic oil and choose XYZ series thin oil station as a matching. The reduction gearbox uses IS0VG320 mineral oil.

5、 Main technical performance

1. According to user needs, the actual configuration may differ slightly from the configuration in the table, and the contract should prevail.

2. The conventional deceleration configuration is belt pulley deceleration, which can be reduced by a gearbox or regulated by a speed control motor according to user requirements.

3. The conventional lubrication configuration is a dry oil pump, and a thin oil station can be used according to user requirements.

4. The conventional configuration does not come with a cyclone dust collector, but can be equipped with a cyclone dust collector according to user requirements.

六、Installation and commissioning requirements

1. Installation of equipment

(1) Basic laying out: Based on the process layout and equipment size, benchmark laying out is carried out, and the floor slab must be chiseled and cleaned before the foundation can be made.

(2) Fixed foundation: Pour 4 concrete supports with an elevation of 150mm to make the surfaces of each support flat, with an elevation error of no more than 2mm (it is best to embed 16mm thick steel plates on the concrete support surface).

(3) Shell installation: The shell is gently placed on the support according to the process layout and leveled with a cushion plate, and then welded and fixed with the embedded steel plate. The installation of the shell flange should be smooth, and asbestos rope should be added between the flanges for sealing. There should be no air leakage during operation.

(4) Installation of transmission support: Before installation, carefully check whether the main shaft and rotor have been deformed or damaged during transportation. Only after confirming that there are no problems can installation be carried out. The main shaft, support, bearing oil pipe, and cylinder cover can be lifted together after being connected.

2. The installation of the whole machine is completed, and the horizontal error of the upper cover is not more than 2/1000.

3. Trial operation

After the installation inspection is qualified, the trial operation can be carried out. The main contents of the trial operation are as follows:

(1) Check the rotating part. When the spindle is in a vertical state, it rotates flexibly without any jamming.

(2) The rotation direction of the rotating part should be consistent with the inlet direction of the air guide blade, and not opposite.

(3) After the installation of the powder selection machine, an appropriate amount of lubricating oil should be added to each lubrication point, and then a trial run of 4-8 hours (at high speed) should be conducted to check the oil supply of each bearing. Only after the trial run is fully qualified can it be put into production.

七、 Operation, maintenance, and overhaul

There are many factors that affect the production efficiency of the powder selection machine, and they are interrelated. In order for the powder selector to achieve high efficiency in the grinding system, it must be operated by experienced technical workers.

1. Maintenance

In order to ensure the long-term safe operation of the powder selection machine, attention should be paid to daily maintenance of the machine. The factory should develop operating procedures and maintenance and repair systems that are in line with the actual situation of the factory.

(1) Each bearing should be regularly lubricated with lubricating oil to ensure sufficient lubrication at each lubrication point, and all lubricating agents for each bearing must be clean. If there is a rustling sound in the bearing, it is caused by dirt and abnormal lubrication, and it must be inspected and cleaned of impurities in a timely manner.

(2) The temperature of each bearing shall not exceed 60 ℃.

(3) Regularly pay attention to the balance of the powder selection machine, and if any abnormal vibration is found, stop the machine in time for inspection and elimination.

(4) The air ducts should be regularly cleaned of dust, and at the same time, rainwater should be prevented from entering each pipe to avoid dust agglomeration.

2. Maintenance

Maintenance of the powder selection machine: The maintenance door should be opened for maintenance after the machine is stopped and the temperature in standby mode decreases and dust settles. During maintenance, a "under maintenance" sign must be hung at the electrical switch control to prevent accidental driving and injury. After the maintenance is completed, the original person should remove the label to indicate that the maintenance is complete before starting the vehicle.

The main contents of maintenance should be determined based on inspection results and usage experience, generally including the following:

(1) Clean and inspect the spindle, bearings, and oil seals. If they exceed the specified values, they should be replaced.

(2) Are the nuts at each connection loose or damaged? If they exceed the specified value, they should be replaced.

⑶ Remove the dust adhered to the shell and pipeline.

Check for wear on the rotating cage and other vulnerable parts of the grading ring (rotor), and replace them promptly if necessary.

八、Product fineness adjustment

If the fineness of the finished product from the powder selection machine is too fine, the rotor speed can be reduced by variable frequency speed regulation or speed regulating motor until the fineness meets the requirements. If the requirements are still not met, the system air volume can be appropriately increased. If the finished product is too coarse, the adjustment method is the opposite.

9、 Precautions for use

1. Strengthen operational management.

2. The powder selection machine has high efficiency and low cyclic load. It is recommended to use a cyclic load rate of 100-200%.

3. The system should be well sealed, and a locking device should be added to the coarse powder outlet.

4. Fineness adjustment is generally achieved by adjusting the rotor speed, and air volume adjustment should be avoided as much as possible.

【Technical parameter table】

| Specification and model | production(t/h) | Air volume(m3/h) | Manual dry oil pump | model | Motor Power(kW) |

| Technical Parameter |

| M350 | 10~14 | 21000~24000 | SGZ-8 | YCTL225-4B | 15 |

| M500 | 14~20 | 35000~42000 | SGZ-8 | Y180M-2 | 22 |

| M700 | 20~28 | 42000~55000 | SGZ-8 | Y200L-4 | 30 |

| M1000 | 28~36 | 60000~75000 | SGZ-8 | Y225M-4 | 45 |