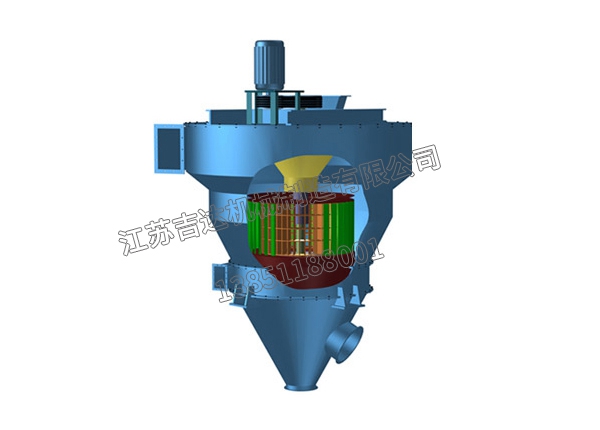

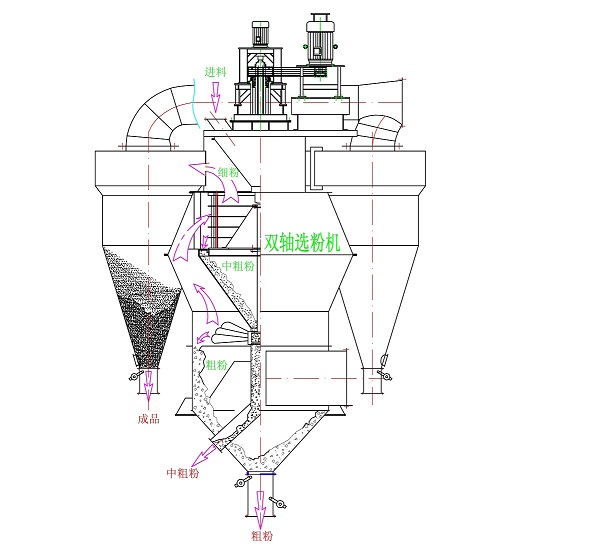

Working principle of dual axis dual rotor eddy current powder separator

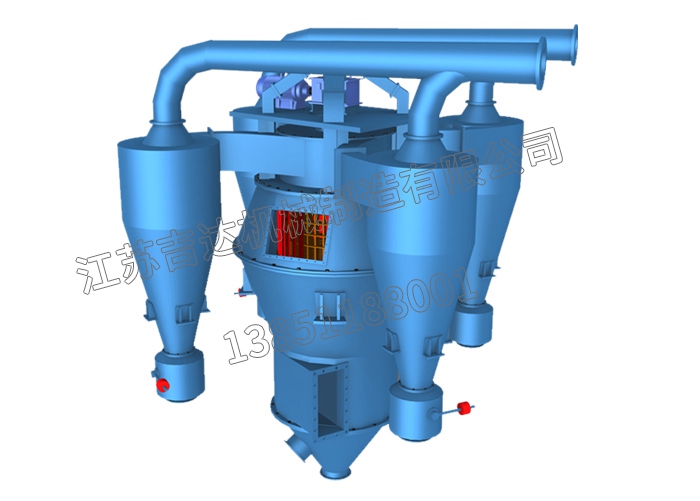

The dual axis dual rotor eddy current powder selection machine is an upgraded product. The powder selection machine is equipped with two sets of rotating systems, each driving two rotors to truly achieve material separation (fine powder, medium coarse powder, coarse powder), and the particle size of the three types of powder can be controlled and adjusted as needed.

Introduction to the process advantages of dual axis dual rotor high-performance powder selection machine

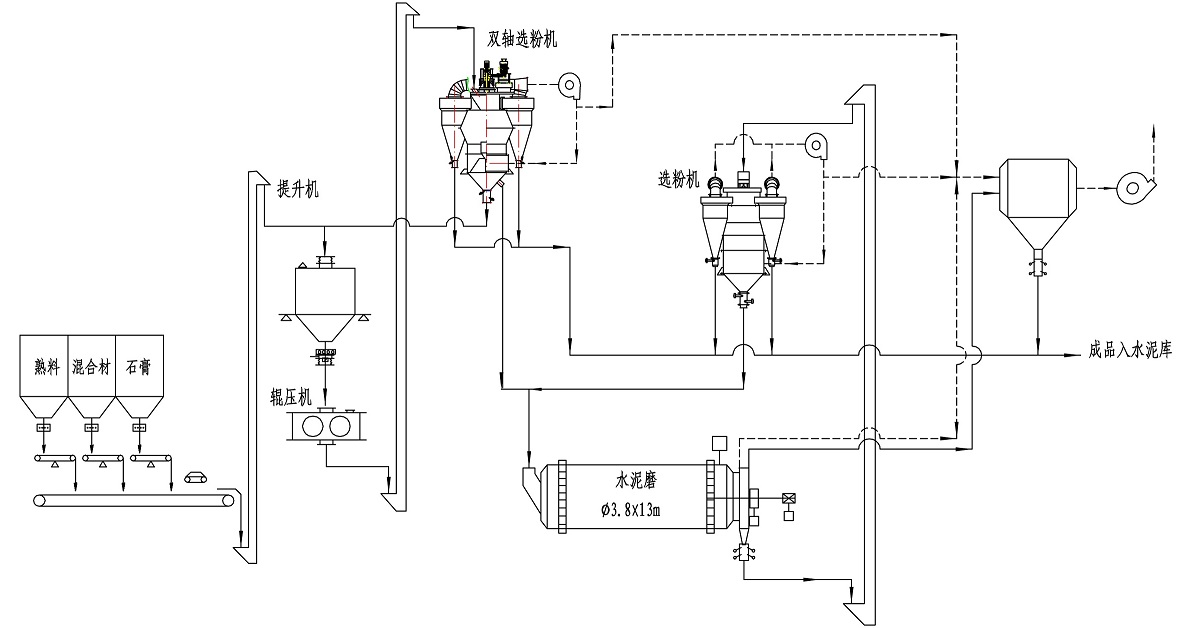

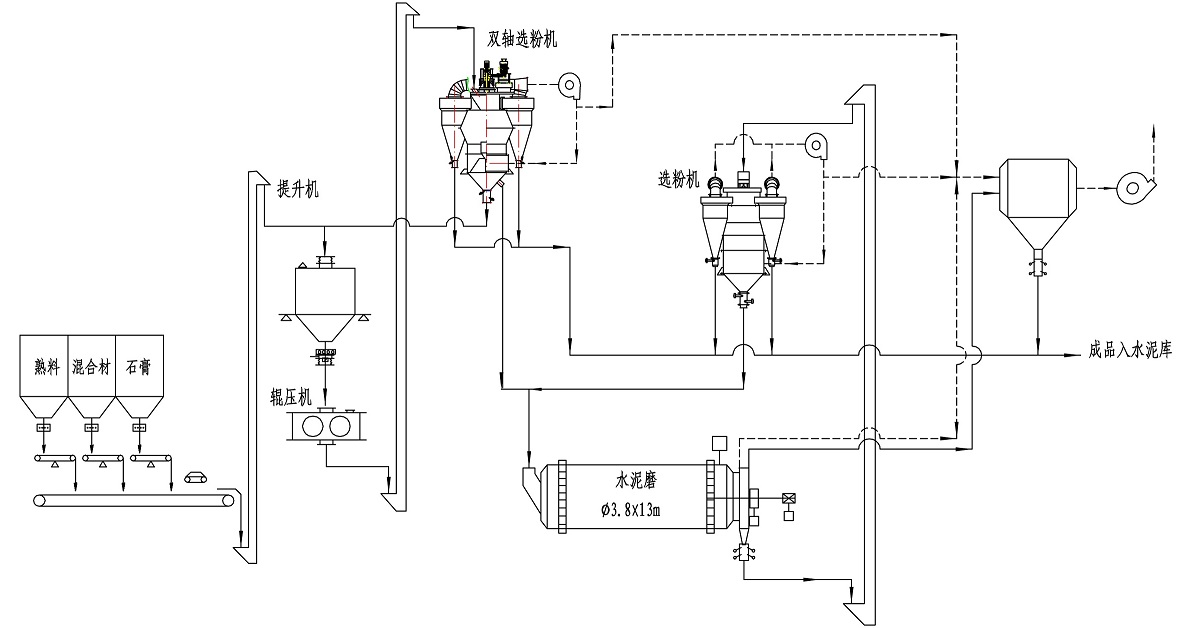

① True Three Separation Material: Three types of materials are classified according to different process requirements, returned to the stable flow bin for large particles, fine powder is selected to enter the finished powder, and medium coarse powder is sent to the ball mill.

② Improve the efficiency of the roller press: The return of fine particles to the stable flow bin is significantly reduced, and the work efficiency of the roller press can be increased to 85%.

③ Improve the hourly output: The V-shaped powder selector is a static powder selector with low powder selection efficiency and no fine powder selection. The use of a dual axis dual rotor powder selector can timely select the fine powder generated by the pre grinding roller, improve the system's hourly output, and most importantly, improve cement quality.

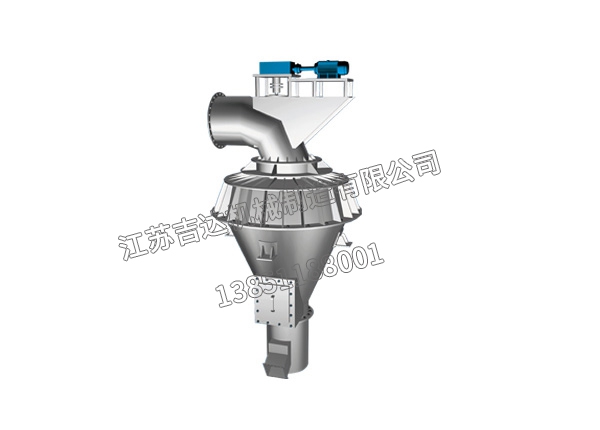

④ Compact structure: Adopting a dual axis dual rotor powder selection machine instead of V-selection, reducing equipment and civil engineering investment for V-selection (V-selection has a high height and large volume). At the same time, the pipeline layout is compact, reducing system resistance and energy consumption significantly;

⑤ Strong adaptability: The dual axis dual rotor powder selection machine solves the problem of moisture sensitivity and low dispersion of V-shaped powder selection machines, especially in the rainy south where the advantages are particularly obvious.

【typical process】

Comparison Table of Powder Selection Machines

| Compare projects | Powder separator type |

| Centrifugal powder selection machine | Cyclone type powder selection machine | Vortex powder separator | Double axis dual rotor eddy current powder selection machine |

| O-sepa | Sepax Vortex powder separator |

| Powder selection efficiency | low | general | tall | higher | Extra high |

| Capacity to increase production | low | general | tall | higher | Extra high |

| Installed power | low | general | Extra high | low | low |

layout | simple | simple | complex | simple | simple |

| Investment payback period | long | long | long | short | Short |

| maintenance cost | centre | tall | tall | low | low |

| Initial investment | small | centre | higher | rising-falling | tall |

![5e23f710527e2[1].jpg](/ueditor/php/upload/image/20250417/1744858411677152.jpg)

![5e23f710527e2[1].jpg](/ueditor/php/upload/image/20250417/1744858411677152.jpg)