1、 Briefly describe

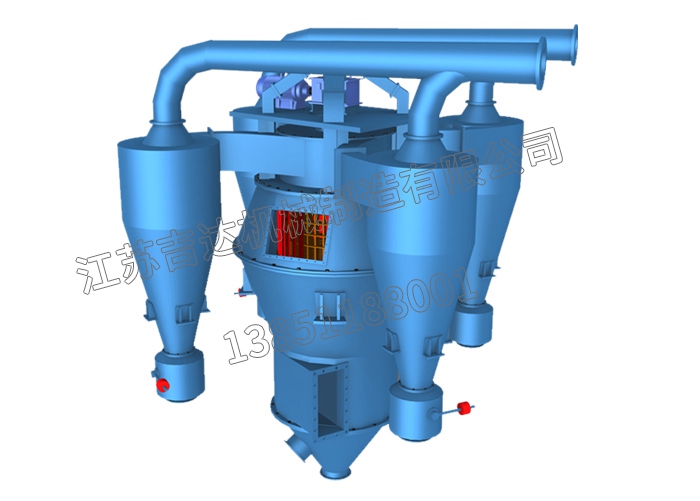

The Sepax high-efficiency eddy current high-efficiency powder separator is the latest technological product jointly developed by our company, Nanjing University of Technology, and Yancheng Institute of Technology, based on the international advanced powder selection principle and using aerodynamic analysis methods. This product breaks through the conventional closed-loop grinding system's "coarse and fine powder" separation theory, dividing the material into three parts: coarse powder, medium coarse powder, and fine powder. The system has a simple process configuration, low energy consumption, and can significantly increase the output of the grinding machine. Its internal structure is reasonable, and the effect of powder selection and production improvement is significant. After implementing the new cement standard, it can effectively improve the quality of grinding system products and guide the trend of technological innovation in powder selection machines.

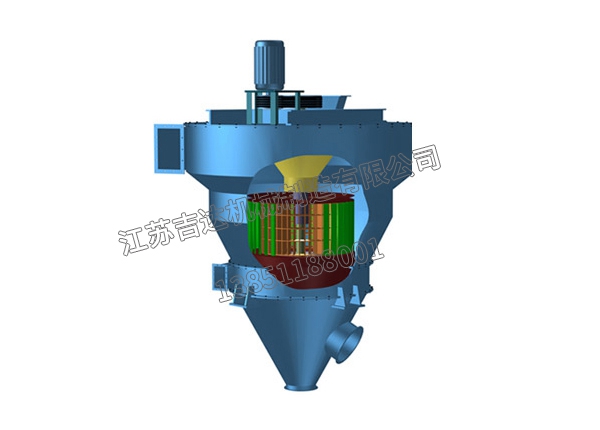

2、 Working principle

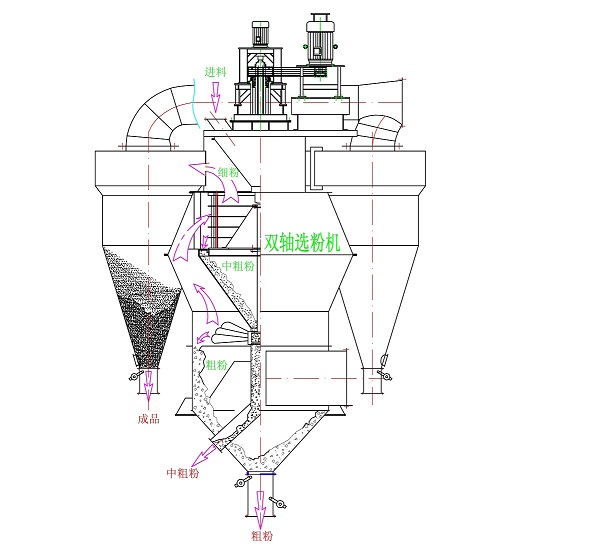

In working condition, the high-speed motor drives the vertical transmission shaft to rotate through the transmission device. The material enters the powder selection chamber through the feeding port located at the upper part of the powder selection chamber, and then falls onto the scattering tray through the upper and lower cones of the medium coarse powder collection cone and the powder passage pipe. The scattering tray rotates with the vertical transmission shaft, and the material is evenly scattered around under the action of inertial centrifugal force. The dispersed material is thrown towards the inner wall of the powder selection chamber by the inertial centrifugal force under the high-speed airflow of the external fan entering the powder selection chamber through the inlet. After collision, the particles lose their kinetic energy and slide down the wall, falling into the coarse powder collection cone. The remaining particles are swept up by the rotating upward airflow and pass through the action area of the large wind blade. Under the impact of the large wind blade, some of the coarse powder particles are thrown onto the inner wall of the powder selection chamber. After collision, they lose their kinetic energy and slide down the wall, falling into the coarse powder collection cone.

After passing through the large wind blades, the medium coarse powder and fine powder continue to rise through the vertical guide vanes and enter the secondary powder selection area under the action of the upward airflow. Under the strong and stable planar vortex formed by the rotating cage rotor, the dusty airflow causes the medium coarse powder to be thrown towards the vertical guide vanes and lose kinetic energy under the action of centrifugal force, falling into the medium coarse powder collection cone and being discharged through the medium coarse powder tube. The fine powder that meets the requirements passes through the cage rotor and enters its interior, then enters the high-efficiency and low resistance cyclone separator with the circulating air, and then slides into the fine powder collection cone to become the finished product.

3、 Technical features

Compared with traditional powder selection machines, the Sepax high-efficiency eddy current high-efficiency powder selection machine has the following outstanding advantages:

1. Divide the material into three parts: coarse powder (d>150um), medium coarse powder (60um<d<150um), and fine powder The coarse powder is returned to the first bin, and the medium coarse powder is sent to the grinding bin of the mill through a high-speed cutter (it can also enter the first bin with the coarse powder). The fine powder, which is the finished product, is directly transported into the warehouse.

2. Compared with centrifugal, cyclone, and rotor separators of similar size, the Sepax high-efficiency eddy current separator has a much higher output and is therefore more suitable for large-scale production needs. The advanced and reasonable structure allows for a wide range of variations in powder selection air volume, output, and feeding amount without affecting powder selection efficiency, and its grading performance is very stable.

3. The principle of grading is advanced. By combining multiple powder selection principles and using aerodynamic analysis methods, the entire flow field was optimized, resulting in significantly reduced equipment resistance, higher powder selection efficiency, and significant energy savings and consumption reduction. The rotor of the powder selection machine adopts a technology that has obtained national patents (a combined powder selection machine ZL number: 20192066684.7). The rotor has eddy current rectification effect, and the airflow inside the rotor only rises relative to the rotor without rotating. After the airflow enters the rotor, the internal momentum moment decreases, which saves driving power and reduces wear. The material undergoes two rounds of powder selection in the powder selection area, resulting in higher and more precise grading accuracy.

4. The spindle of the powder selection machine adopts stepless high speed. The fineness adjustment is convenient, sensitive and reliable, and the adjustment range is wide.

5. The spatial scope of the powder selection area and the lifting area has been re optimized, fully utilizing the main space to increase the material to gas ratio and improve the powder selection efficiency.

6. The vulnerable and wear-resistant parts of the powder selection machine, such as the feeding tray, cyclone tube, snail horn, guide vanes, and rotor, are all made of wear-resistant materials or treated with wear-resistant processes, resulting in extremely low wear rates. The use of a new type of manganese plate effectively extends its service life.

7. The sealing of the main shaft lower bearing adopts a new design scheme, effectively solving the two major problems of bearing dust and lubricating oil leakage, and effectively extending the service life of the lower bearing.

8. When designing the foundation of the powder selection machine, the mechanical vibration reduction principle is adopted to ensure that the resonance frequency between the powder selection machine and the foundation is not close to the natural frequency of the powder selection machine, fundamentally solving the vibration problem of the powder selection machine that has long plagued manufacturers.

9. The coarse powder tube, medium coarse powder tube, and fine powder tube all use double interlocking air valves, greatly reducing the system's air leakage rate and overcoming the previous defect of high dust during the operation of the powder selection machine.

4、 Technical performance

| Powder separator | Specification and model | N500 | N750 | N1000 | N1500 | N2000 | N2500 | N3000 | N3500 | N4000 |

| Technical Parameter |

| Production(t/h) | 15~30 | 27~44 | 35~50 | 50~80 | 70~90 | 90~120 | 110~160 | 130~190 | 144~200 |

Maximum feeding amount(t/h) | 90 | 135 | 180 | 270 | 360 | 450 | 540 | 630 | 720 |

| Select powder air volume(m3/h) | 30000~40000 | 45000~55000 | 60000~70000 | 90000~110000 | 120000~150000 | 150000~180000 | 180000~240000 | 210000~240000 | 240000~280000 |

| Equipment resistance(kPa) | 1.6~1.8 | 1.6~1.8 | 1.6~1.8 | 1.6~1.8 | 1.6~1.8 | 1.6~1.8 | 1.6~1.8 | 1.6~1.8 | 1.6~1.8 |

| Reducer | Model | KF128-K2-180 | KF148-K2-200 | B2SV5 | B2SV5 | B2SV6 | B2SV6 | B2SV7 | B2SV7 | B2SV8 |

| Speed ratio | 9.16 | 4.83 | 5.6 | 6.3 | 6.3 | 7.1 | 7.1 | 7.1 | 8 |

| Electrical machinery | Model | Y180M-2 | Y200L-4 | Y250M-4 | Y280M-4 | Y315S-4 | Y315M2-4 | Y315L2-4 | Y355M2-4 | Y355L2-4 |

| Power(kW) | 22 | 30 | 55 | 90 | 110 | 160 | 200 | 250 | 315 |

| Thin oil station | Model | XYZ-6G | XYZ-6G | XYZ-10G | XYZ-10G | XYZ-10G | XYZ-10G | XYZ-10G | XYZ-16G | XYZ-16G |

| Internet traffic(l/min) | 6 | 6 | 10 | 10 | 10 | 10 | 10 | 16 | 16 |

| | weight(t) | 10 | 12 | 14 | 15 | 20 | 26 | 32 | 42 | 54 |

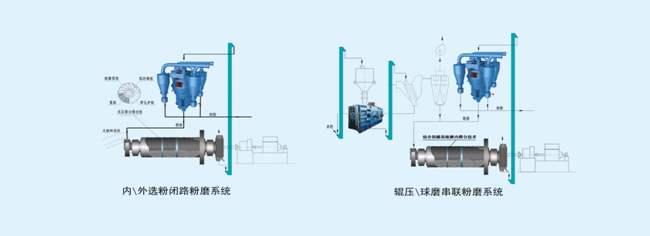

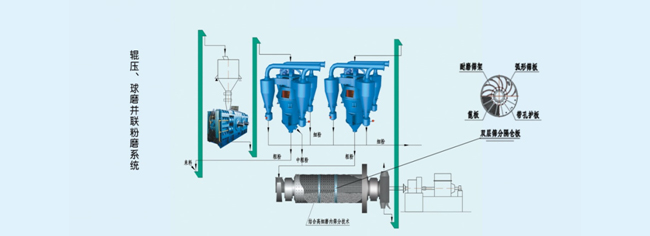

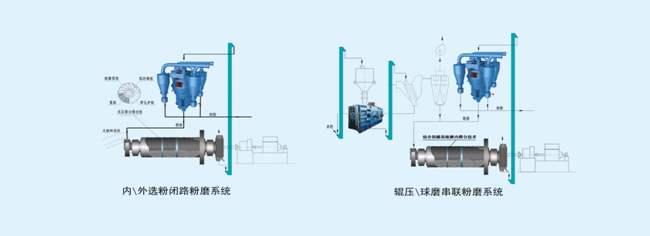

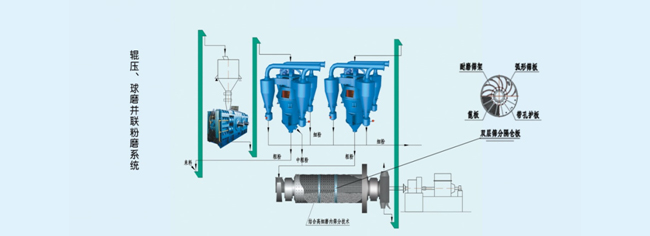

【typical process】