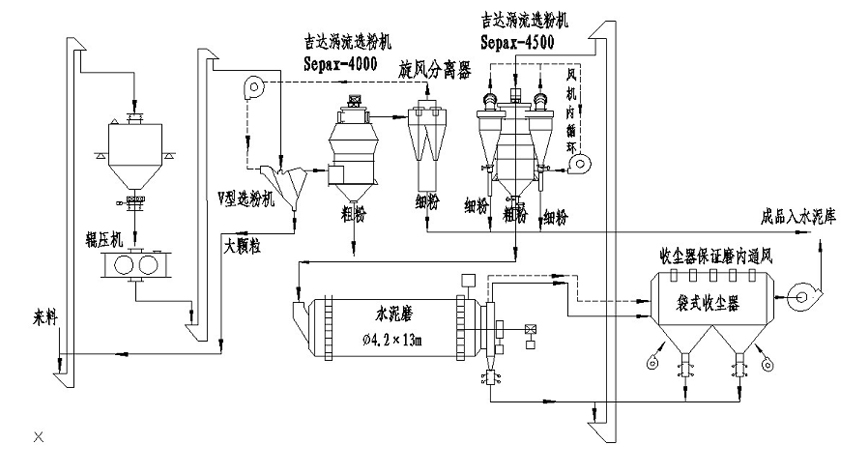

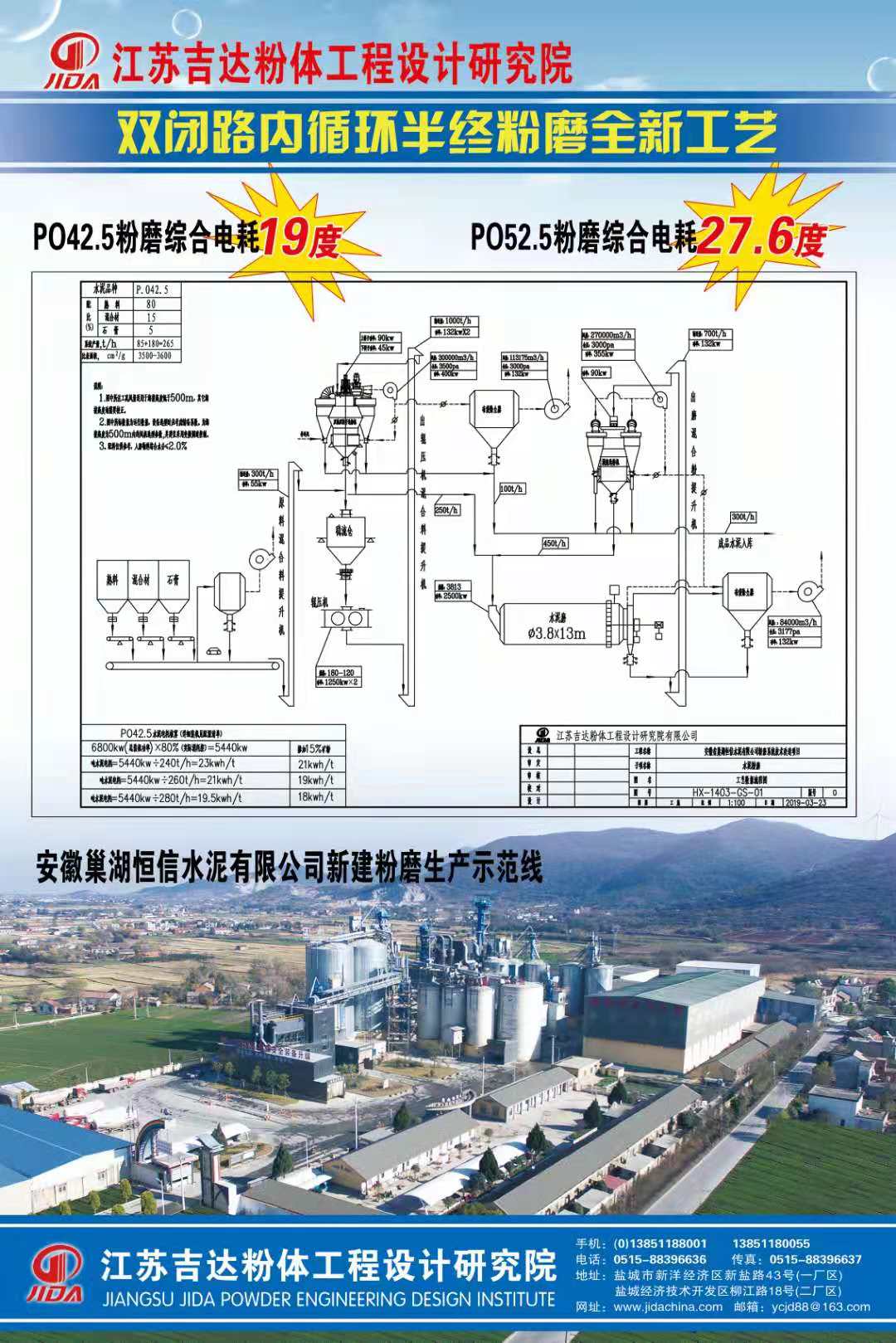

In the roller pressing system, a large amount of qualified fine powder is produced when the material is strongly squeezed by the roller press. The fineness of the material entering the mill can reach 50-70% at 0.08. After being classified by the V-shaped powder selector, it is collected and separated by the cyclone tube and directly fed into the ball mill. In the ball mill, it will form over grinding and material cushion, reducing the grinding efficiency of one bin. Therefore, selecting this qualified fine powder into the finished product will increase the system output while improving the grinding capacity of the ball mill and the working conditions of the mill.

System Characteristics:

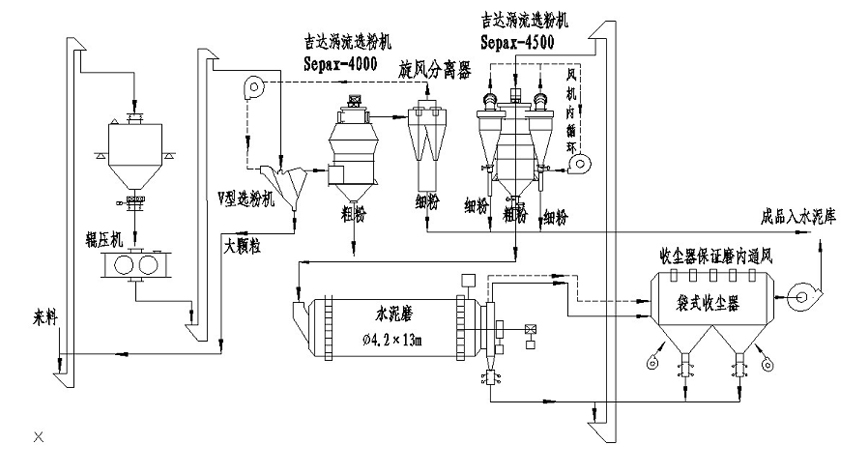

The roller press and ball mill adopt a parallel grinding process, and both devices produce finished products. The output of the roller press contains 10-15% qualified fine powder, which can be selected by the powder selection machine in a timely manner, reducing the material ball ratio in one bin of the ball mill, reducing the phenomenon of material cushion in one bin, and improving the grinding efficiency. The coarse powder sorted out by "V selection" enters the roller press and is squeezed again. The fine powder sorted by "V selection" enters the subsequent Jeddah powder selection machine for precise classification: the finished powder and coarse powder are sorted out, and the coarse powder is sent to the first bin of the ball mill for grinding. The finished powder is collected by the cyclone tube and sent to the finished product warehouse by the conveying equipment.

By using a Jeddah eddy current powder selector in the rolling system, qualified finished powder produced by the rolling machine can be selected. This not only increases the system's output but also reduces the load on the ball mill, minimizes over grinding, and improves the grinding efficiency of the ball milling system. The system has a high hourly output, a significant increase in production, a high operating rate, and low electricity consumption for finished products.